Maximum Accuracy and Production Efficiency

Reduce Misreads with the LECTOR 63x Image-Based Code Reader

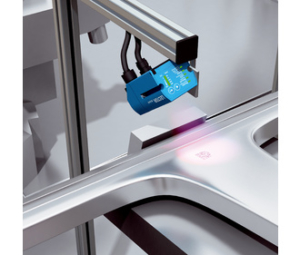

The Lector63x is a flexible image-based code reader. With its high image resolution, compact housing and exchangeable optical design it is well equipped for a variety of needs. It can easily be used for small codes, in high production speeds or for long-range identification. The Lector63x is easy to handle: quick optical exchange, intuitive user interface, aiming laser, beeper, LED feedback and MicroSD card – simplifying setup, operation and maintenance!

SICK image-based code readers are applied to maximize your accuracy and production efficiencies by reducing misreads caused by conditions such as low quality codes, the orientation of the code and the depth of your code reading field. Springfield Electric’s Automation Specialists can provide an extension of your design team. Their expertise will help you plan for today while keeping future growth in mind.

Send a message to a member of Springfield Electric’s Automation team. Or call us at 800-747-2101

Download White Paper >

Fields of Applications

- Presentation camera for manual parcel sorting

- Automated sorting systems in CEP and retail

- End-of-line aggregation for food or pharma packaging

- Track and trace in automated packaging machines

- Long-range identification for traceability in automotive

- Tire identification

- High-resolution code reading in electronics and solar

Examples of Applications

Traceability of devices

The identification, and so too the traceability of parts over the entire production process is quite a challenge. The Lector63x image-based code reader directly identifies marked parts with an extremely high scanning performance. Thanks to the 4Dpro technology from SICK, a large number of network integrations, such as PROFINET and EtherNet/IP, are available.

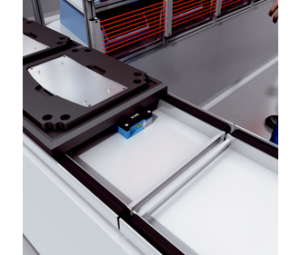

Traceability of products in the production process

The RFID transponder ensures traceability to all assembly stations. Product information and derived individual production commands on the transponders can be both read and written using the RFH620 interrogators at a frequency of 13.56 MHz.

Identification of product content, supplementary sheet, label, and packaging through linear or 2D codes

When a product is packed, it is important to ensure that the packaging, label, and supplementary sheet are used in the correct combination. Errors can result in expensive complaints or even health risks if, for example, people with allergies take dangerous substances due to incorrect product information. The Lector63x image-based code reader can reliably read and match up medical packaging. Intelligent identification algorithms ensure that different 1D, 2D, and stacked codes, and plain text can be read on all kinds of materials. Intuitive setup with aiming laser, focus adjustment, and auto-setup reduces training and installation time and costs.

Full traceability of pharmaceutical packaging

In order to ensure end-to-end traceability, every item of packaging must be labeled with an individual Data Matrix code. This label is also required for serialization of the individual packagings. After the packaging is filled, for example, with tablets that use blister packs as their primary packaging, Lector63x image-based code readers capture the coding during the packaging flow to verify its legibility by a machine on the one hand, and coded contents on the other.

Multiple code reading on PCB panels

The Lector63x image-based code reader can identify all codes on a printed circuit board panel. The special software script makes it possible to selectively output or serialize individual codes according to customer requirements. The read rate can be raised considerably by recording several images from different angles. Thanks to its large field of view, the Lector63x can flexibly record codes regardless of their position, contrast ratios or conveyor speed. This means, for example, that retrofitting is no longer necessary when reading different E-card designs.

Manual parcel sorting for loading and unloading processes

Throughput optimization, efficiency gains, and improved workplace ergonomics are the main objectives when designing manual sorting stations. The permanently installed image-based code reader Lector65x helps to meet these objectives. Unlike hand-held scanners, this code reader allows employees to have both hands free at all times. The camera’s large reading range and depth of field enables the object to be automatically identified as soon as it is picked. This allows this essential process step to be integrated into the manual sorting process whilst ensuring optimal ergonomics.