Save Time & Automate Processes on the Farm

The Farm Owner Wanted to Automate Some Processes for a Newly Constructed Grain Site.

Background:

While the electrical contractor on the project had not engaged in a controls project with Springfield Electric’s application engineers, he had pursued PLC and HMI programming and VFD start-up previously. He knew this could be a tedious and time-consuming task when it is not something you do every day. The contractor would lean on the efficiency the Springfield Electric’s specialists could provide in programming as well as for product specification for the equipment to ensure good connectivity and communication in the system. The contractor could then focus on several other aspects of the project including electrical and mechanical installation and contracting of the project.

Project Details:

As with any project, the process begins with gathering information and listening. The project scope was defined as what products and which engineering services would be provided by Springfield Electric. The contractor provided desired product connection assembly and process flow, as well as which equipment to automate and control. He also provided the team with details/specs for the equipment (Voltage, HP, Amperage, etc.) in the project.

Solution:

Springfield Electric engineers provided a Schneider Electric PLC and HMI solution to control the grain site per the contractor’s requests. The team worked closely with the contractor to ensure the programs developed would follow the process flow exactly as required. In addition, the engineers included some monitoring and alarming within the program to allow for ease of troubleshooting the system in the future. These small added features help reduce future downtime.

Prior to shipping, the Springfield Electric team completed the programming and ran equipment through in-house quality checks. Once installed by the contractor, the Springfield Electric team commissioned the system onsite and trained the contractor on how to operate and navigate the custom-designed interface. The team also completed five VFD start-ups used for controlling the pit motors and overhead conveyors.

The benefit of this project to the contractor was the savings in labor investment in the project. Instead of spending time developing the PLC and HMI code, he was able to focus valuable time on all remaining parts of the project. As result, he was able to be more efficient overall in the completion and success of the project. Discover more Agriculture Control System Solutions here.

Control Interface Examples

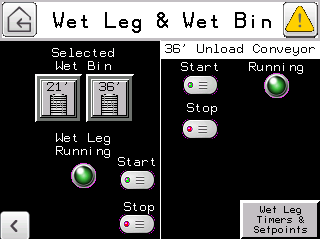

Figure 1: Wet Bin Auger and 36’ Unload Conveyor start/stop control and running indication.

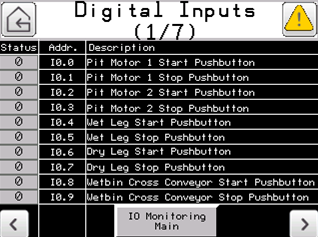

Figure 2: The “Addr.”, the physical terminal the device described in the “Description” column is wired. When voltage is sensed on that terminal, the “Status” column will turn green and show the number 1. This assists the contractor in troubleshooting by knowing if the PLC is receiving specific signals without having to get into the panel and check voltages.

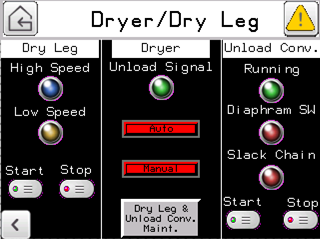

Figure 3: This graphic visualizes the controls for the pieces of equipment related to the drying process. It also indicates when switches are actuated or not. The diaphram and slack chain switches are used as interlocks, to shut down certain pieces of equipment when tripped. This process protects the equipment from damage.

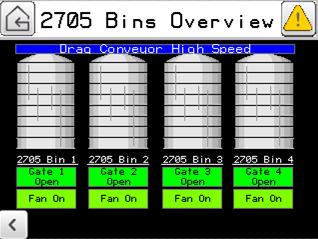

Figure 4: This GUI shows the overall status of the equipment associated with a group of storage bins. The user can see the status of grain bin storage:

- Gate – open or closed

- Fan – on or off

- Overhead Conveyor – running or stopped

Springfield Electric’s team of Automation Engineers & Specialists support Agriculture Control Systems

From engineering services on equipment controls for small pieces of your operation to a large scale operational needs. Our team specifies connected products that communicate across your operation, providing you real-time monitoring and control.

Request an Equipment Automation Consultation

Please leave your information in the form below and a representative will reach out to you.